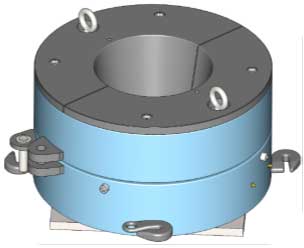

Casing Spider Table

Due to the increased drilling and development of the heavy oil sands, the design of the conventional drill rig has changed. While most refurbished rigs have changed over to using top drives, they still have maintained their rotary tables. Many new rig designs like the super singles and slant rigs have done away with rotary tables and rely on their top drives to supply all rotation requirements. In many operations of drilling, the top drive equipment can meet all drilling and completion requirements for the well. In some cases, long horizontal sections may require tubular rotation during casing installation and cementing. If the rig does not contain a rotary table, rotation may not be available.

The Casing Spider Table (CST) is simply a large bearing assembly (similar to a rotary table) that has the capability of holding the casing string weight while rotating the casing string. The CST contains an API tapered center hole, which can occupy most casing and drill pipe slips. The CST also has split bushings, which fit the tapered center hole, to allow smaller slips and casing to be run. The CST can be attached to drilling rigs without rotary tables to allow rotation with other equipment other then top drives. The CST can be placed over the existing centre hole of the rig and can be secured using chains. The CST is designed so that the bottom portion stays stationary while the top portion is allowed to rotate. During times where the top drive is not accessible, other equipment like power tongs can apply torque to the casing set in the CST. As the torque is applied to the casing above the CST, the bearings located within the CST allows the casing and the top portion of the CST to rotate while the bottom portion of the CST stays stationary. The CST allows rotation to keep casing from getting deferentially stuck in the well bore. The CST also allows the casing to be rotated during cementing processes and will deliver better cementing bonds.

APPLICATION:

- All types of drilling and service rigs that do not possess rotary tables.

- Vertical, directional and horizontal wells requiring casing rotation.

FEATURES:

- Can contain casing sizes from 10 ¾” diameter and lower.

- The bushing taper is API standard and allows use of standard casing and drill pipe slips.

- Bearing system to handle most casing string dynamic and static loads.

BENEFITS:

- Allows casing rotation.

- Helps eliminate deferentially sticking or stuck casing.

- Helps develop better cement bonds.

- Easy installation to all types and styles of rigs.

- Can withstand high dynamic and static loads for hours of continuous operation.