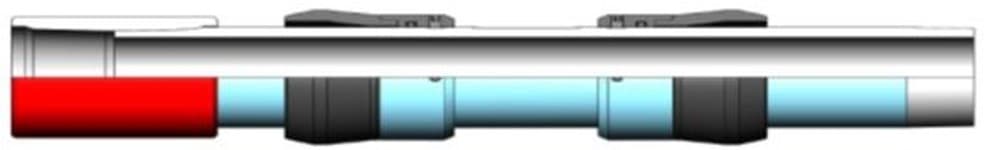

Debris Seal Cup Packer

Depending on the well application, there are times where a debris seal is required to contain contaminants or to isolate specific well zones from other zones within a well. When these two components are required on a removable well packer, the Debris Seal Cup Packer (DCP) is an economical and reliable choice.

In many thermal wells, the seal required must be maintained during the movement of the packer within the casing it resides in due to thermal growth. Many thermal packers will be subject to thermal growth movements or may be required to be removed from the well. Some liquid inflatable packers will fail from extreme temperatures. Some cement filled inflatable packers, or packers containing permanent slips, are not easily removed from the wellbore. Similar swellable packers can also be difficult to be removed from the wellbore.

The DCP will allow thermal movement while delivering seal and debris containment. The DCP is made with a steel body and uses different thermal elastomer compounds for the cup design, depending on the well. The ID and OD of the DCP are custom built to fit both the liner size that it’s installed on, as well as the casing size it will be installed into. The DCP steel body is manufactured to drift diameter, which centralizes the cups and help eliminate wear to the elastomeric element while running in or pulling out of the wellbore. More than one DCP can be installed to the liner at the same depths if required. Once the DCPs are in place, pressure applied to the pressure side of the DCP will seal the element to the casing wall, and the ID of the DCP (containing seals) will seal to the liner or mandrel body. They allow high pressure sealing in either direction, in multiple locations, and are compatible in both thermal and cold wells.

The DCPs can be run in conjunction with instrumentation lines. Through ports in the steel body of the DCP can contain multiple lines without affecting the seal. The DCP can also be run individually on the top of casing strings to act as a Debris Hanger. It can be released with the casing string mechanically or Hydraulically.

APPLICATION:

- Cold and thermal wells (vertical or horizontal) requiring debris seals or zonal isolation’s.

- Wells requiring these debris seals or zonal isolation’s packers to move with thermal expansion.

- Wells that require the removal of these debris and zonal packers from the well bore.

- Wells where instrumentation lines are required.

- Mechanical or Hydraulic release of liners requiring top bi-directional debris sealing.

FEATURES:

- Elastomeric materials tested to 650°F and 5,000 psi.

- Wear resistance during installation and removal from the wellbore.

- Easy installation to the liner, in either direction, at predetermined depths.

BENEFITS:

- Allows thermal growth movement, while maintaining a seal.

- Provide sealing in either direction.

- Economical.