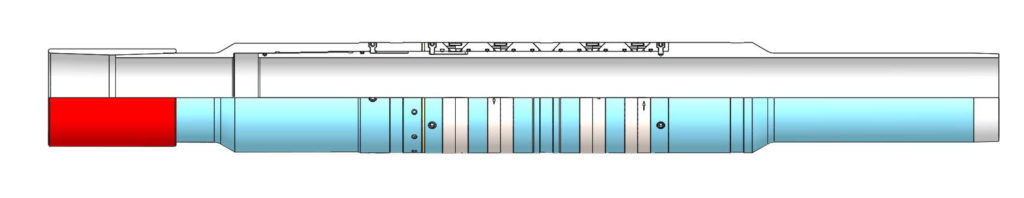

Sliding Sleeve Packer

The Sliding Sleeve Packer (SSP) is designed for use in wells that are subject to extreme temperatures and pressures. Wells that use steam to assist in heavy oil recovery are subject to thermal expansion and contraction on various casing and tubing strings within the wellbore. The use of elastomeric elements often fails under these conditions. The SSP uses no elastomeric elements. The SSP design uses stainless steel elements that will not wash, wear, or corrode, and have higher longevity.

The SSP is designed to create a debris seal to the inside diameter of the casing it is set in. Mechanical rotation is required to expand the sealing elements to the casing diameter. Left hand rotation of the drill or tubing string at surface will expand the seals. Right hand rotation will decrease the seal diameter and disconnect the seal from the casing wall. The SSP assembly is equipped with a No Turn Tool (NTT), which will allow rotation within the SSP tool to set the seals. All rotational, compressive, and tensile strengths, as well as drift diameters of the SSP, are designed to API standards.

To operate and set the SSP, place it within the wellbore at the desired depth. Left hand rotation will start to expand the stainless-steel seals until they come in contact with the inside diameter of the casing that it resides in. Reciprocation of the string will slide the SSP within the casing. The exact drag of the SSP seals against the casing inside diameter is achieved by either adjusting the right hand turns to decrease the drag, or adjusting the left hand turns to increase the drag. Once the required drag is achieved, the SSP can be re-positioned to the desired depth. When multiple SSPs are run in a single well for zonal isolation, the shear pin assembly of the SSPs will be used. Rotation of the string in either direction will engage the NTT. The NTT assembly will release as soon as any upward or downward movement is applied to the string. Having the ability to set the drag load of the SSP seals from surface allows the operator to make future changes to the SSP seal drag without having to remove the tubing string from the wellbore. Proper setting of the seal drag can eliminate buckling or parting of tubing strings due to thermal movements. To remove the SSP string from the well (or multiple SSPs), simply rotate the string to the right until torque is indicated. This places the seals of the SSP back to original drift diameter and can be removed from the well.

APPLICATION:

- To provide a continuous casing seal/debris seal at a desired set drag, during thermal tubular movements at high temperatures and pressures.

- Zonal isolation for multiple zone wells.

FEATURES:

- Installation and seal settings are done mechanically and not hydraulically.

- Stainless steel seals are non-corrosive and have high wear resistance to enhance sealing and wearing from downhole movements, temperatures, and pressures from steam applications.

- No elastomeric materials are used for sealing applications. All SSP seals are stainless steel.

- Manufactured with high grade materials to API specifications.

- Can be set in either a vertical or horizontal position.

- Multi SSPs can be set from surface, in wells for zonal isolation.

BENEFITS:

- Setting of the seal drag loads can be done from surface, without removal of the string. The SSP can be removed from the well if required and can be re-installed without replacing any of the sealing components.

- Can replace the use of expansion joints and set packers.