Zone Isolation Block

Optimal distribution of steam can significantly improve the recovery factor of a heavy oil or bitumen reservoir. Thermal recovery utilizing steam, has been extensively and successfully used in many heavy oil wells.

Although steam injection has enhanced oil recovery, history has also shown us that steam injection has created challenges. Some of these challenges result in having steam break though on Steam Assisted Gravity Drainage (SAGD) wells, or unwanted water production through lower zones in horizontal wells, or thermal expansion causing failure to seals and hangers. These problems can result in costly work-overs associated with down hole equipment failures, reduced recovery, or loss of the well.

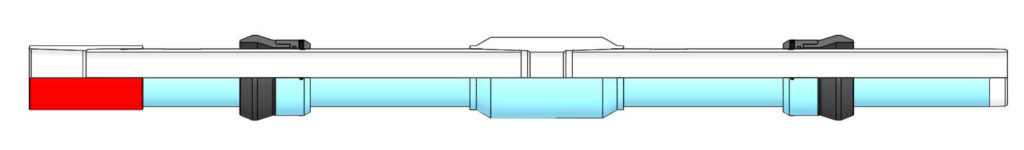

When zone isolation is required, the Flow Control Device (FCD) liners used for injection or production, would be installed within the production string already containing Zone Isolation Cylinders (ZIC). Refer to Zone Isolation Cylinders (ZIC) for further information. The FCD liners will contain the Zone Isolation Blocks (ZIB) at predetermined depths. These zone separations will assist in solving the challenges previously mentioned.

The ZIB are installed within the FCD liner and will coordinate with the locations of the ZIC within the production liner previously installed in the well. Each ZIC installed within the production liner will decrease in inside diameter (ID) as the depth of the liner increases. The coinciding ZIB will also decrease in outside diameter (OD) by the same amount as its mating ZIC. When the FCD liner’s ZIB line up with the production liner’s ZIC, the ZIB will slide inside their mating ZIC to complete a seal. The ZIC and ZIB work in conjunction with the FCH liner to inject, produce, or isolate specific sections of the well.

The ZIB are manufactured to tight tolerances and are hardened for durability. The ZIB will slide within the ZIC. The ZIB not only provide zone isolation, they also provide protection from thermal expansion movements to the FCD liner.

APPLICATION:

- Thermally enhanced oil recovery applications – steam injection wells.

- High temperatures and pressures wells require sealing capability during pipe movement.

- Vertical or horizontal well zone Isolation to enhance steam distribution, shut off steam or water break through.

FEATURES:

- Hardened and non-corrosive finish of steel seals eliminating washing.

- Optional positive memory steel seals.

- Capable of running Instrumentation lines and containing seal.

- Optional high pressure/temperature elastomer cup seals.

BENEFITS:

- Easy installation requiring only string weight to set.

- Ability to isolate zones to decrease work over costs, or permanent loss of well.