Casing Tension Anchor

Wells that use steam, or any other type of heat, to enhance the performance of production are often subjected to certain stresses created by the extreme heat. Steam creates a thermal expansion and contraction of all materials that reside in the steamed well. Even casings that are cemented in the wellbore are subject to these thermal loads. When drilling horizontal wells, the intermediate casings (through the build section of the well) are cemented in place. The production casings (through the horizontal section of the well) are typically set with a casing hanger at the bottom of the intermediate casing and are not cemented.

When the horizontal well is exposed to the heat from the steam, the casing materials will expand. The hung horizontal casings that are not cemented are allowed to move in the formations and also through the casing hanger. During the cooling of the materials, when the steam is shut off, it will cause the casing to contract. When these loads are exposed to casings that are cemented in place, the casings are not allowed to move because of the cement, and these stresses are then absorbed by the material of the cemented casings. Typically when the intermediate casing is cemented in place, it is either in a compressed or somewhat relaxed state. Since the bottom of the casing is not anchored, the casing can never be in a state of tension when it is cemented in place. Although the heat from the steam expands materials, the cemented casing material (unable to move) actually goes into a compressive state. This can cause buckling of casing tubes and failure to threaded connections within the cemented string.

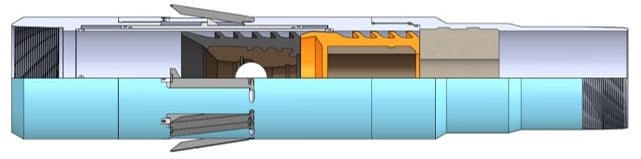

The Casing Tension Anchor (CTA) is an anchor that is installed on the bottom of the intermediate casing and will be activated at the end of the cementing job. The CTA contains rigid fingers on the exterior that are pressure activated or released by the top plug that passes through the interior of the CTA. At this point when the cement job is completed, the casing can be lifted up by the rig. As the casing moves up, the fingers of the CTA will dig into the formation and hold the casing from moving (anchored). This will allow a calculated amount of tension to be place in the whole string of the intermediate casing. This tension will be held by the rig (or slips) as the cement is allowed to cure. Once the cement has hardened, the rig can release the tension from the casing. Now, when steam is subjected to the intermediate casing and places it in a compressive state, the residing tensile load in the casing will help absorb or neutralize the thermal compressive load, which could otherwise cause damage to the intermediate casing tubes and connections.

APPLICATION:

- For use in thermal or heated wells having cemented casing in the wellbore.

FEATURES:

- Ability to place casing strings in tension during cementing jobs.

- Reduces the stress placed on cemented casing strings, created from thermal expansion and contraction.

- Is pressure activated at the end of the cement job using typical cementing tools (top plug).

- Activates at the end of the cement job, allowing rotation and movement of the casing during cementing process.

BENEFITS:

- Can reduce casing damage or failure to cemented casing strings, typically caused by heat (thermal expansion).