Multilateral Window Level 2

A sidetrack well is one that is started down hole from an existing well. A deflective device is fixed within the existing well’s casing down hole, and the new well is started by drilling (deflecting) through the existing casing. A typical window is drilled through the casing by hydraulically setting a ramp at the deflection direction required. The drill bit will follow the ramp and drill through the casing. After the well is drilled, casing is run in the sidetrack well and is guided into the well by means of the same ramp. This ramp has bypass capability so the original well below can produce past the ramp. This type of lateral window is considered a level 2 well, where one leg of the well cannot be isolated from the other leg of the well. Lateral windows that can allow a seal between each well leg are considered level 6 lateral wells.

This type of level 2 window does not allow re-entry into the lower well because the new lateral casing and the ramp block its entry. If entry to the lower well is required, the upper lateral casing and the ramp must be removed from the main well casing. If the ramp and casing is required to be put back in the well, it is difficult to line up the ramp at the exact location to re-enter the lateral well window. Typically, it can take 8 to 12 hours to drill through the existing casing and to dress the drilled lateral window.

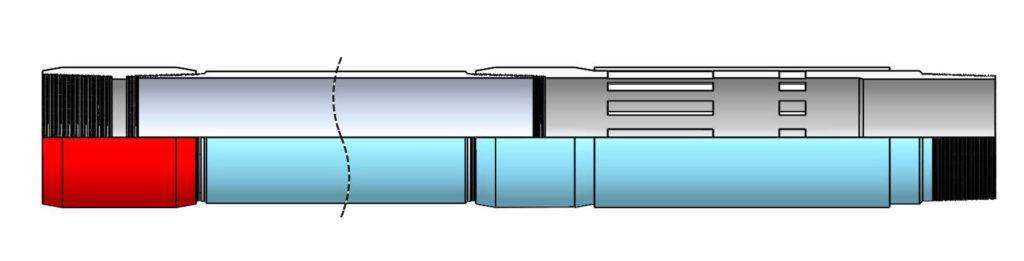

Knowing when a new Multilateral Window Level 2 (MW2) well is to be drilled, the main casing of the main well will contain an aluminum joint with a female spline sub attached below it. The ramp will contain a male spline sub below it. The ramp is installed (with MWD and drill bit) into the well and is set inside the female spline sub at the direction/orientation required. Drilling of the MW2 window (through the aluminum joint) can be drilled and dressed in 2 hours. The lateral window casing is run with a specific tool, placing the top of the lateral casing at the inside of the window and removing the ramp with the same trip. The lower well is accessible past the lateral casing top. When access is required to the lateral well, the ramp is re-installed into the splines at the exact orientation and depth as it was when drilled, allowing easy access to the lateral well. This ramp also has through production capability if left down hole.

The ramp attaches to the drill string with a retractable shear pin sub. When the spline sub of the ramp is installed into its matting female spline sub at the desired orientation, weight is applied to shear the pins. The spline sub cannot pass through the matting sub when the splines are attached. Passage through the spline sub is allowed when the splines are detached. These splines can be locked and unlocked every 6° for 360°.

APPLICATION:

- For use in drilling multi-lateral wells, where one or more windows are required from the same main casing. These wells are level 2 wells, which contain no isolation/sealing capabilities from other laterals in the main well.

FEATURES:

- Precise orientation and depth setting of the ramps.

- Removal and re-installation of ramps from the main well with exact orientations and depths.

- Ramp passage through one locking spline sub, to other spline subs at lower depths (multiple windows).

- Aluminum drilled windows for fast drilling and dressing.

BENEFITS:

- Faster drilling and tripping times, compared to other typical multi-lateral window systems.

- More than one window drilling capability on one well with access to all wells drilled.

- Passage past existing lateral wells through the main well.

- Reusable ramps.