Hydraulic Release Tool

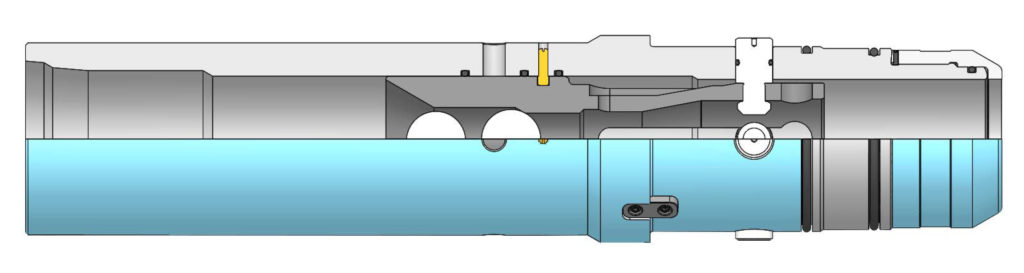

The design of the Hydraulic Release Tool (HRT) is different than other release tools in the manner of which it grips to the body of the tool it is releasing. Many of the release tools on the market rely on gripping either the inside and/or outside diameter of the tool it is releasing. These types of grips are unable to withstand high torsional values. The HRT relies on pins to connect to the tool it is releasing. The HRT’s drive blocks can withstand extremely high torsional loads which allow rotation of strings down hole at high torque without failure. The HRT’s drive pins provide the compressive and tensile strengths. The HRT operates by using the drilling fluids and mud pumps on the rig. The unique design of the HRT allows operation with any type of fluid. The shear pin design of the HRT does not require high shear pressures; the in-place rig pumps are sufficient to operate the HRT.

Functioning of the HRT requires a ball to be pumped from the surface, down inside of the drill pipe, to the HRT to activate the release. Plastic balls are pumped from the surface. When fluid displacement is unwanted through pumping, steel balls can be used to reach the HRT without fluid displacement. Once the ball has reached its seating position within the HRT, pump pressure is applied to shear the shear pins. Once the shear pins are sheared, the HRT piston slides down, relocating the HRT pins and dislodging the HRT from the tool to be released. Disengagement from the released tool is achieved by simply lifting the HRT up. The repositioning of the piston allows drainage/circulation of the drill string after release.

When releasing, the neutral point of the HRT is not critical. The HRT can be released in a compressive state which eliminates the use of other tools required to find free point. With the aid of the HRT torque blocks, the tool can be released with induced torsion loads.

APPLICATION:

- To release down hole tools hydraulically on vertical and horizontal wells.

FEATURES:

- Releases hydraulically.

- Produces higher torque values than inner/outer diameter grip type release tools.

- Tool design allows no compressive or torsion loads to the pins.

- Release position allows for pipe drainage.

- Manufactured with high grade materials.

- Releases in vertical or horizontal positions.

- Can be operational with cement slurries.

BENEFITS:

- Does not grip to the inside or outside diameters of the released tool (no die marking).

- Minimal pump pressure required to release (eliminates the use of a pump truck).

- Release position of the tool can be neutral or compressive.

- Tool can be released with torsion loads applied.

- Release of the tool can be monitor through pump pressure.