Hydraulic Retrievable Hanger

Oil and gas wells often have several casing strings installed in the wellbore. Some casing strings extend from the bottom depth to the surface while other casing strings may only line the lower portion of the wellbore. A typical example of this situation in a wellbore would be an intermediate casing string cemented in place to surface. The production casing would then extend from the bottom of the cemented intermediate casing to the bottom depth of the drilled wellbore. This production casing would be set or hung near the bottom of the intermediate casing using a casing hanger. This eliminates the need to run production casing to surface through an area of the well that is already cased. This can reduce the cost of completing a well.

Depending on the well type, casing hangers can vary in design. In vertical wells where the production casing is hung off the bottom portion of the intermediate casing. Directional slips are provided with the hanger to hold the production casing from slipping and moving down the wellbore. Depending on the wellbore pressures, these directional slips may be required to prevent upward movement of the production casing in the wellbore. In some thermal wells, the production casing may be required to have no movements in both directions, while other thermal applications require freedom of movement, using no slip assemblies at all.

These casing hangers are also equipped with an element or seal, which are activated and set during the process of setting the bi-directional slips. The setting movements of the components within the casing hangers are either mechanically or hydraulically controlled. The elements or seals of the hangers are made of an elastomer material and can be designed for either cold or thermal environments. Custom designed features of the elements allow for higher pressure sealing than conventional elements.

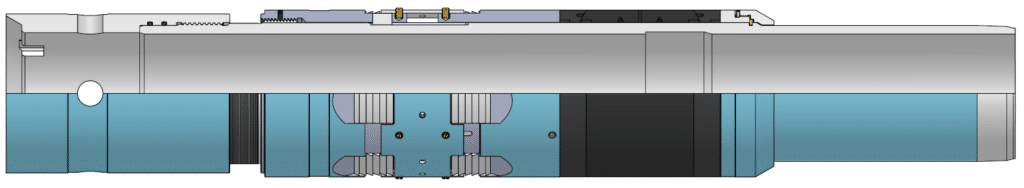

The Hydraulic Retrievable Hanger (HRH) is set, hung, and released hydraulically and is mechanically retrieved/obtained from the wellbore. The design of the slips on the HRH will not allow them to fall off the tool or drag when retrieving/obtaining the tool to surface. The hanger is also available in hydraulically set but non-retrievable (HNH).

APPLICATION:

- Vertical and horizontal wells.

- High temperature and high-pressure wells.

- Multi directional anchor requirements.

FEATURES:

- Hardened and non-corrosive finish to the slip & ratchet components, and mandrel.

- Ratchet ring assembly provides a positive memory to the sealing elements.

- Can be hydraulically set and mechanically removed

BENEFITS:

- Can be set using rig pumps. No high-pressure Pumps are required to function the HRH.

- Ease of deployment and retrieval of the HRH

- The slip assemblies reduce the risk of stuck hangers and fishing jobs.

- Ratchet system provides a positive continuous pressure to the sealing elements.

- Highest temperature and pressure ratings on thermal seal elements.