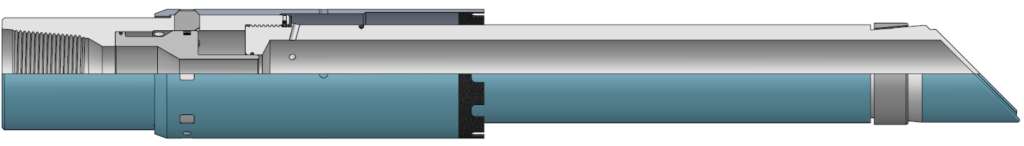

Hydraulic Mill-Out & Retrieval Tool

The Hydraulic Mill-out & Retrievable Tool (HMR-HP) is specifically designed to be used for the High Pressure Hydraulic Retrievable Hanger (HRH-HP). When High Pressure (HP) retrievable hangers are obtained or retrieved from the wellbore, they differ from the typical Mechanical Obtain Tools (MOT) used for lower pressure Hydraulic Retrievable Hangers (HRH). To release any hanger, the slips and seals that engage to the annular casing must be relaxed. When a MOT is used to retrieve a standard HRH, the MOT is connected to the hanger using drive pins. A tensile load is applied to the hanger from surface, which shears screws on a retainer ring. This ring when sheared, releases any applied loads to the slips and seals, allowing its removal.

On HP hangers, the slips and seals are set using very high pressures. To release these contained high loads, it would require substantial tensile loads to release a retaining ring. The high pressure Hydraulic Mill-Out and Retrieval tool uses a milling face to remove the ratchet ring of the HRH-HP, which permits the release of the stored loads. Once milling is completed, a ball is dropped to hydraulically release the milling sleeve and permit the stinger of the HMR-HP to lower into the hanger. The catch ring located on the stinger connects to an internal profile of the HRH-HP and allows its removal from the well.

APPLICATION:

- For use in vertical or horizontal wells.

- For use in retrieving High Pressure Retrievable Hangers from a well.

FEATURES:

- Tool features allow milling operation and retrieving operation on one trip.

- Does not require extreme tensile loads to release the slips and seals.

- Quick milling times.

- Disconnect features.

BENEFITS:

- Economical means of retrieving high pressure hangers.

- Safe tool replacing high tensile loads

- Reduce the risk of equipment damage from high tensile loads.