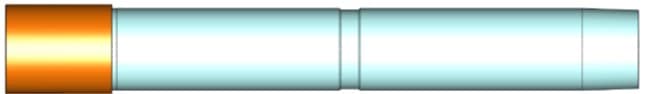

Casing Separation Sleeve

When steam recovery is used in heavy oil wells, formation movements are often encountered. These formation movements can crimp, shear, buckle or pull casing strings apart. Heavy oil sands are usually found between bed rock and shale. These shale upper and lower formations are usually consolidated rocks, which normally hold pressures when not fractured. When steam is induced into these oil sand formations, its heat, pressure, and volume will cause the sands to swell, causing movement of the surrounding shale formations. Vertical movement between the upper and lower formations containing the sands can move in excess of 1 meter.

Most producing or injecting wells will usually enter the upper formation into the sands, but usually don’t penetrate the lower shales. This will protect the casing string from seeing most of these vertical formation movements.

Instrumentation or observation wells can often be placed through the upper formation, sand formation, and lower formation in order to monitor formation movements. Casing failure in these wells is usually inevitable but controlling where the casing fails has its benefits.

The Casing Separation Sleeve (CSS) is manufactured from casing that mate to the connections of the casing being run. This CSS has an engineered machined groove cut to the outside diameter of the CSS. Different depths of this groove will create different tensile strengths. The CSS is placed in the casing string so when the string is cemented in place, the CSS is positioned in the sand formation. As the two shale formations expand away from each other during steaming, the tensile load applied to the fixed casing will fail at the weak machined groove of the CSS.

Having the failure occur within the oil sand formation, rather than outside the sands in the shale formations can have its advantages.

APPLICATION:

- For use in steam injection fields where formation movements are evident.

- Instrumentation and observation wells.

- Vertical and horizontal wells

FEATURES:

- Capability to engineer and control the amount of load to cause the CSS failure.

- Has the same characteristics as the matting casing (i.e. threads, diameters, grades).

BENEFITS:

- Control exact depth of casing failure down hole.

- Still have access to the oil sand formation after the casing failure.