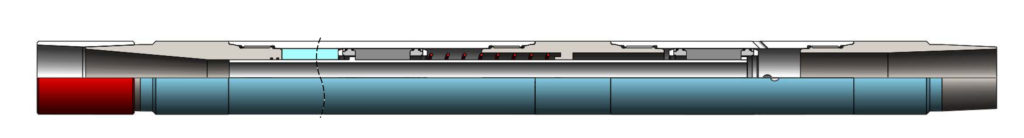

Heat Shifting Diverter

Many wells that use heat, specifically steam, to enhance the production of heavy oil can encounter problems. On Steam Assisted Gravity Drainage (SAGD) wells, some of these problems can range from steam breakthrough to water production.

On a SAGD paired well, where the injection (steam) well is horizontally placed above the production (oil) well, steam breakthrough from the injection well to the producer well can occur. When this happens, steam can circulate from the injector well to the producer well and back to surface without properly heating the heavy oil, leaving it in place. Another problem that can occur in these wells is a breakthrough of groundwater into the production liner and having it being produced before the heavy oil. Some of these problems can be controlled using other tools, but all must be manipulated from the surface.

The Heat Shifting Diverter (HSD) is a tool that could automatically open or close (shift) on its own, down hole, without having to manually manipulate the tool from the surface. The HSD would mostly be run on the production well. Depending on how the HSD is setup, it could either open ports or close ports by the heat conditions below ground found in the well or the formation. If, for example, steam breakthrough from the injector to the producer was a concern, the HSD on the producing well would be designed to close ports when the well temperature would increase to a set point, stopping steam to enter or breakthrough to the producer. This would divert the steam into the formation rather than to the production well. After a period of time, the well temperature would drop at the point of steam breakthrough. The HSD that closed in this location would now reopen due to the cooler temperatures.

The automatic shifting (opening or closing) of the down hole ports in the HSD, are controlled by different types of solid materials having different boiling points. These solid materials are contained in cylinders within the HSD and are connected to sliding sleeves. As the boiling points of the solid materials are reached, the expansion of the solid (now liquid), will allow the sliding sleeves cover to reveal port holes on the HSD. Designed springs are placed on the opposite sides of the sleeves to counteract with the cylinders. For example, when the heat melts and expands a solid, the cylinder opens, shifting the sleeve and compressing the spring. Depending on the design, this will either open or close the port holes. When the temperature cools, the solid will contract causing the spring to open, shifting the sleeve and closing the cylinder.

APPLICATION:

- On vertical or horizontal wells using heat to enhance oil production.

- Where unwanted steam or water breakthrough may occur.

- Where well head choking is required to control breakthrough of steam/water down hole.

FEATURES:

- Automatic shifting of sleeves to down hole, to divert the flow of fluids or gases.

- Manual shifting of down hole tools from surface not required.

- Automatic down hole tool shifting is heat sensitive.

- The HSD is pre-designed to either open or close ports at a set temperature.

BENEFITS:

- Can reduce the chance of steam breakthrough or channeling on SAGD wells.

- Can reduce the chance of water production

- No surface equipment required to manipulate down hole tools.

- No choking of well production at surface. Increased production.