Retrievable Bridge Plug

Many applications in the oil and gas industry may require sealing off a wellbore from the surface after drilling is completed. Some of these applications are well abandonment, well cementing, well testing, zone isolation, or temporarily shutting in of a well for completion equipment servicing. Depending on the application that a bridge plug is used for, it will determine the type of bridge plug required, and the depth that the bridge plug will be set at. In most cases, the bridge plugs will be set and/or released using standard tubing or drill pipe strings.

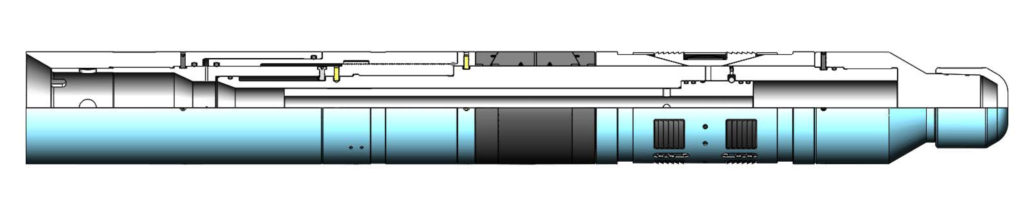

The Retrievable Bridge Plug (RBP) is a compact tool which contains a seal assembly, bi-directional slips, a ratchet assembly, and a by-pass valve. The RBP can provide sealing capabilities up to 5,000 psi and high temperature applications up to 60°F. The seals are set with hydraulic pressure using the rig pumps. The bi-directional slips are hydraulically set simultaneously with the seals. The bi-pass valve is set in the closed position when being set and is automatically opened during the retrieve/obtain process of the RBP. The outside dimensions of the RBP are that of casing drift, both in the running and retrieval operations, to allow ample space for fluid by-pass. The unique design for RBP does not require the use of drag block assemblies to set or release the tool.

To set the RBP at the desired depth, apply rig pump pressure to set the slips and seals. Once set, a ball drop and pump pressure procedure will release the drill string from the RBP. To retrieve the RBP, attach to the RBP downhole using the Mechanical Retrieve/Obtain Tool (MOT) and right-hand rotation. The by-pass valve will open prior to the seals and slips releasing. Further rotation will disengage the seals and slips and return the RBP to its original drift diameter for easy removal from the wellbore.

The RBP is also available in our One Trip System (OTS). This allows the setting of the RBP immediately after setting the casing hanger on the same trip.

APPLICATION:

- Vertical and horizontal wells.

- High Temperature and high-pressure wells.

- Isolations and work-overs (temporary)

- Abandonments and cementing (permanent)

FEATURES:

- Hardened and non-corrosive finish to slip & ratchet components, and mandrel.

- Ratchet ring assembly provides a positive memory to the sealing elements.

- By-pass valve to equalize pressure prior to releasing and retrieving.

- Can be hydraulically set and released.

- Can be mechanically retrieved/obtained.

- Retains drift diameters during movements inside the casing.

BENEFITS:

- Can be set using rig pumps. No high-pressure pumps are required to function the RBP.

- Ease of deployment and retrieval of the RBP

- Ratchet system provides a positive continuous pressure to the sealing elements.

- High temperature and pressure rated thermal seal elements.