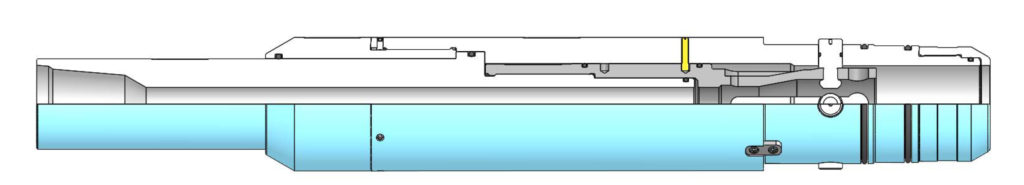

Mechanical Obtain Tool

Many tools and tubular are intended to be left down hole in many types of wells. The most common of these would be casing strings. When running a string of production casing, it is more economical to run the casing from the bottom of the well to the bottom of the intermediate casing and hang/seal it at this position. This eliminates running the entire string of casing to surface within a previously cased hole.

The required amount of casing is assembled and then run into the well to a determined depth using drill pipe above the casing. At the change over area (casing to drill pipe), there is usually a seal type casing hanger and some type of release mechanism. Once the seal or casing hanger is activated and set, the release mechanism is activated, separating the drill pipe from the hanger, allowing the drill pipe to be removed from the well and leaving the production casing in place down hole. The release mechanism can be activated mechanically or hydraulically.

Mechanical refers to any mechanical means used like pulling (tensile loads), pushing (compressive loads), or rotating (axial loads) to activate a mechanical device for either releasing or obtaining. Hydraulic release refers to any hydraulic means used like fluid flows or pressures to activate a mechanical device for either releasing or obtaining. Depending on the well and its circumstances, either a mechanical or hydraulic release or obtain type tool will be chosen.

This Mechanical Obtain/Retrieval Tool (MOT) will retrieve/obtain using rotation. The MOT is designed with pins to grip the tubular. The MOT does not use gripping ties to hold the tubular it will retrieve, like some conventional mechanical retrieve tools. The MOT relies on pins that extend through the body of the tubular it is retrieving at four positions 90° apart. The top of the tubular will also contain four torque slots where torque blocks on the MOT would reside. The four pins will withstand all compressive loads while the torque blocks withstand the torsional loads. When retrieving the tool, the 4 pins will hold the tensile loads. To activate the MOT, right hand rotation will shear a pin and allow further right-hand rotation, which causes the pins to extend into the tubular to be retrieved/obtained. The MOT can release and re-attach to the tubular down hole if required.

APPLICATION

- For use in retrieving/obtaining tubular down hole in vertical or horizontal wells.

- Mechanical retrieval using right hand rotation only.

FEATURES

- No gripping ties used that can slip or fail, and damage the tube being retrieved.

- Can be released and re-attached down hole if required.

- High torque, tensile and compressive load capabilities.

- Right hand rotation to activate the tool will not cause unwanted connections to back-off.

- The torque blocks relieve any torsional and compressive loads to the pins.

BENEFITS

- Additional tooling is not required to find neutral point.

- Can be functioned in a compressive state.