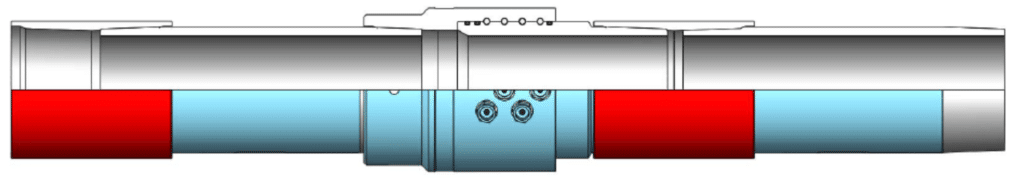

Casing Swivel

Casing Swivels (SWV) are generally used above the rig floor and are attached within a casing string. The purpose of the Casing Swivel is to allow rotation of the casing below the swivel while rotation above the swivel stays stationary. These swivels are mostly used during cementing jobs where the Cement Head and cement lines above the rig floor need to stay stationary. When the slips are set directly below the SWV to the casing string, the rotary table or power tongs will allow rotation to the casing string below the swivel. The SWV contains ball bearings and is not designed to handle high dynamic loads. The ball bearing design allows for rotary movement only. The SWV should not be subjected to any high tensile or compressive loads. When picking up the casing string with the swivel still attached to the string, the casing elevators should be attached to the casing below the swivel. The Casing Swivels are equipped with grease fittings to maintain the ball bearing and seal life. The swivel should be greased prior to every use.

In cases where a swivel needs to withstand high dynamic loads, a different bearing system is used. These bearing types are called thrust bearings and are designed to handle high dynamic loads. These swivels are built using the same bearing systems found in mud motor bearing assemblies. These types of swivels are mostly used in drill pipe strings and not casing strings.

APPLICATION:

- To be used in casing strings during cementing jobs

- To separate rotation between the casing string and the Cement Head equipment.

- To be used in drill strings where separation of rotation within the string is required.

FEATURES:

- Ball bearing system for minor rotational loads.

- Thrust bearing system for high dynamic loads.

BENEFITS:

- Allow separation of rotation within a string of casing or drill pipe.

- Increase cement bonds using casing movements.